The Critical Role of Spectral Accuracy: Understanding Peak Wavelength and FWHM in 365nm UV Industrial Inspection Lamps

In the precise world of industrial non-destructive testing (NDT), the ultraviolet (UV) inspection lamp has evolved from a simple light source into a critical metrological instrument. For applications ranging from fluorescent penetrant inspection (FPI) and magnetic particle testing (MT) to counterfeit detection and quality control, the accuracy of the lamp's output is paramount. Two parameters stand out as the most vital indicators of performance: the accuracy of the peak wavelength and the Full Width at Half Maximum (FWHM). Understanding these metrics is essential for selecting the right tool to ensure flaw detection is reliable, repeatable, and compliant with international standards.

The Significance of 365 Nanometers

The choice of 365nm is not arbitrary. This wavelength, residing in the UVA spectrum (315-400nm), is optimally matched to the excitation properties of the fluorescent dyes and pigments used in NDT processes. These materials are engineered to absorb UVA energy and re-emit it as brilliant yellow-green or orange visible light, creating a stark contrast against the dark background. However, if the lamp's peak wavelength deviates significantly from this ideal, the efficiency of this excitation plummets. A lamp emitting at 355nm or 375nm may appear bright to the human eye but will fail to excite the fluorescing agents with maximum efficiency, resulting in dim indications, missed defects, and ultimately, catastrophic component failure.

Peak Wavelength Accuracy: The Target Matters

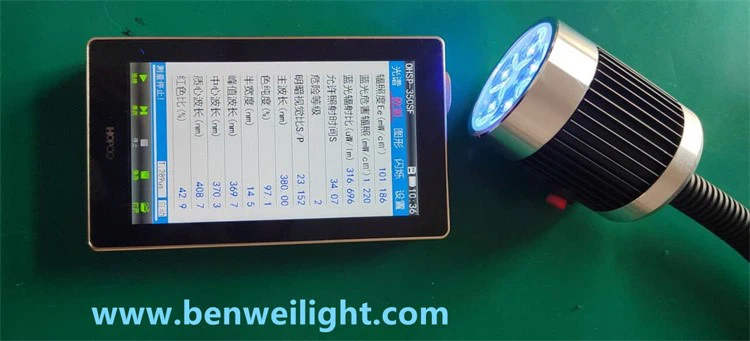

The peak wavelength is the specific wavelength at which the lamp emits its highest intensity of radiation. For a tool billed as a "365nm" lamp, accuracy is everything.

The Industry Standard: High-quality, professional-grade UV-A lamps are engineered to produce a peak wavelength as close to 365nm as possible. The accuracy for a superior instrument is typically within a very tight tolerance of ±5 nm (i.e., 360nm to 370nm). Many top-tier manufacturers specify an even tighter tolerance of ±3 nm.

Consequences of Inaccuracy: Inexpensive or poorly designed lamps often utilize LEDs without proper filtering, leading to peaks that can drift into 385nm or even 400nm. This "blue-leak" or broader spectrum contains visible light, which washes out the fluorescent indication, drastically reducing contrast and inspector eye fatigue. The resulting dim glow makes subtle cracks and imperfections invisible to the inspector.

Full Width at Half Maximum (FWHM): The Need for a focused Spectrum

While hitting the right peak is crucial, the purity of that light is equally important. This is where Full Width at Half Maximum (FWHM) comes into play. FWHM is a measure of the spectral bandwidth of the light source. It represents the width of the emission spectrum (in nanometers) at half of its maximum intensity. A smaller FWHM indicates a purer, more monochromatic light source.

The Ideal FWHM: For critical inspection work, a narrow FWHM is non-negotiable. A high-quality 365nm LED-based inspection lamp, equipped with a precision bandpass filter, will typically have an FWHM of ≤ 20 nm, with advanced models achieving ≤ 12 nm.

Why a Narrow FWHM is Critical: A narrow FWHM ensures that almost all the emitted energy is concentrated tightly around the 365nm peak. This eliminates the deleterious effects of extraneous visible light (blue leak), which compromises the inspector's dark-adapted vision and reduces the signal-to-noise ratio of the fluorescent indication. It is this spectral purity that creates the "true black" background against which defects shine with maximum brilliance.

Factors Influencing Spectral Performance

Achieving this precise optical output is a feat of engineering:

LED Chip Quality: The inherent spectral characteristics of the UV LED chip itself are the starting point.

Bandpass Filters: This is the most critical component for achieving purity. A high-quality dielectric filter is placed over the LED to selectively block all unwanted wavelengths outside the very narrow UVA target window.

Thermal Management: UV LEDs generate heat, which can cause wavelength drift (a phenomenon where the peak shifts with temperature). Effective heat sinking and thermal management are essential to maintain spectral accuracy during prolonged use.

Conclusion: Accuracy is Synonymous with Safety

In industrial inspection, what you can't see can hurt you. The accuracy of the peak wavelength and the narrowness of the FWHM are not mere technical specifications; they are the fundamental determinants of an inspection lamp's ability to reveal critical defects. Investing in a lamp with a verified peak wavelength of 365nm ±5nm and an FWHM of 20nm or less is an investment in product integrity, workplace safety, and regulatory compliance. It transforms the inspection process from a subjective visual check into a reliable, repeatable, and truly non-destructive test.