Illuminating Natural Beauty: The Art of LED Backlighting for Granite, Marble, and Onyx

In high-end interior design, granite, marble, and onyx are not merely materials-they are the soul of a space. However, it is when these million-year-old natural stones meet cutting-edge LED backlighting technology that their true beauty is truly "awakened." A uniform, soft glow emanating from within the stone instantly transforms cold walls and heavy countertops into vibrant art installations. This is more than just lighting; it is a profound dialogue between light and material. This article will reveal how to use customized LED light panels to precisely control light, making every inch of the stone's veins and textures radiate breathtaking brilliance.

Why are LED Light Panels the Only Choice for Stone Backlighting?

When it comes to giving stone a "luminous" vitality, traditional light sources often fall short. Halogen lamps generate threatening high temperatures, fluorescent tubes struggle to achieve uniform halos, and ordinary LED strips can create annoying hotspots. Professional-grade high-lumen stone backlighting LED solutions have become the industry standard due to three irreplaceable advantages:

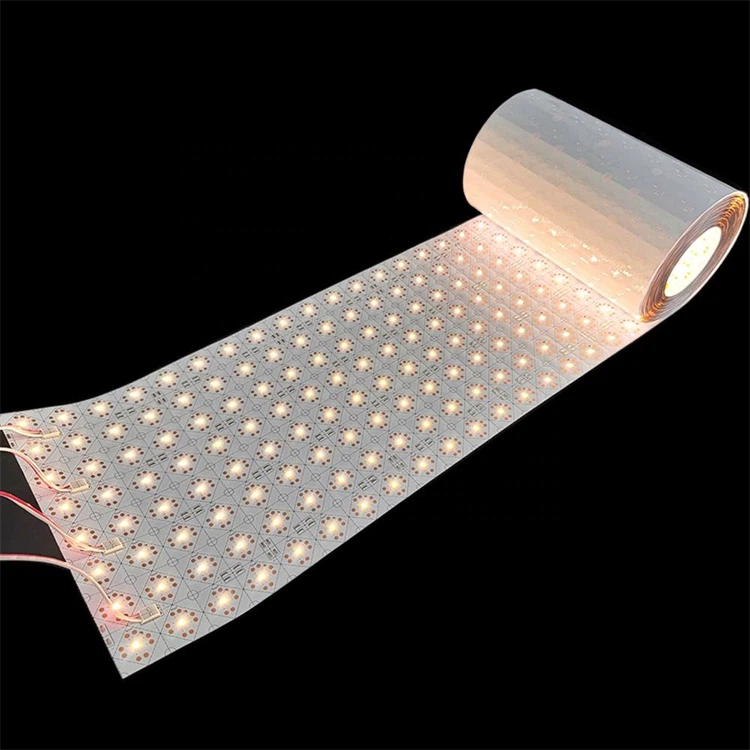

Ultimate Uniformity, Transforming into a "Light Body": The core goal is to turn the stone itself into a uniform area light source. High-quality LED panels employ dense chip layouts and scientific light guide designs to ensure light emanates evenly from every inch of the stone's back, completely eliminating spotty hotspots and creating a natural, gradient effect like dawn piercing through clouds.

Precise Light Control, Interpreting Material Authenticity: The mineral composition, crystal structure, and thickness of different stones result in vastly different light transmission and diffusion characteristics. The brightness (lumens) and color temperature of LED panels can be precisely matched to the stone's properties. For example, darker granite with poor translucency requires higher-brightness panels, while semi-translucent onyx is better suited for medium-to-low brightness to showcase its warm texture.

Safety and Durability, Integrated into the Building's Life: Once installed, stone backlighting projects are nearly irreversible. LED panels feature low operating temperatures and no UV radiation, avoiding potential long-term thermal stress damage to the stone. A lifespan exceeding 50,000 hours means they can coexist with the building's structure, requiring no maintenance.

Backlighting Solutions for Different Stone Types

To achieve optimal results, solutions must be "tailored" to the natural characteristics of the stone. The table below compares the backlighting needs and solutions for three typical stone types:

| Stone Type | Core Characteristics & Optical Challenges | Recommended LED Panel Configuration | Expected Effect & Design Key Points |

|---|---|---|---|

| Onyx | High translucency, layered textures like a painting. The challenge is that light can easily "pass through" without depth. | Medium-Low Brightness (1500-2500 lm/ft), Warm White (2700K-3000K). Prioritize panels with a diffusing layer. | Highlights the dramatic layers of internal veins, creating a warm, mysterious, amber-like glow. Ideal for bar fronts and feature accent walls. |

| Marble | Semi-translucent to slightly translucent, rich veins (e.g., Carrara White). The challenge is balancing vein visibility with overall halo uniformity. | Medium-High Brightness (2000-3000 lm/ft), Natural White (3000K-4000K). Ensure the panel mounting surface is absolutely flat. | Light diffuses softly, veins appear subtly, presenting an elegant, luxurious light quality. The premier choice for hotel lobbies and high-end bathroom walls. |

| Granite | Mostly opaque, only a few dark crystalline varieties have local light-transmitting properties. The challenge is creating a modern sense of "edge-glow" or "local translucency." | Ultra-High Brightness (3000+ lm/ft), Cool White (4000K-6000K). Use high-density edge-lit LED panels for illumination from the sides/edges. | Aims not to make the entire stone glow, but to outline contours or make crystals "sparkle," creating a cool, high-tech visual effect. Suitable for modern-style counters and installation art. |

Core Parameters for Perfect Stone Backlighting

The key to success lies in a deep understanding and precise control of the following technical parameters:

1. Luminous Flux & Illuminance: The Science of Brightness Calculation

"3000 lumens per foot" is a useful starting reference, but the actual required brightness needs precise calculation. The formula is:

Total Lumens Required = Stone Area (sq. ft.) × Target Surface Illuminance (foot-candles) ÷ Stone Light Transmittance

Light Transmittance: Must be obtained from the stone supplier or tested via a sample (typical ranges: Onyx 10-40%, Marble 1-15%, Granite <5%).

Target Illuminance: Decorative backlighting typically aims for 100-300 foot-candles, while functional lighting (e.g., counters) requires 500+ foot-candles.

Professional designers use optical simulation software for previews, ensuring a light uniformity ratio (minimum/maximum) greater than 0.8.

2. Color Temperature & Color Rendering: Shapers of Mood and Authenticity

Color Temperature Selection: This directly defines the space's mood. 2700K-3500K Warm White significantly enhances the stone's warmth and solidity, suitable for creating luxurious, intimate atmospheres; 4000K-6000K Cool White highlights the stone's purity, modernity, and technological feel, making textures appear sharper.

Color Rendering Index (CRI): It is essential to choose LED panels with a CRI > 90 and a high R9 (red rendition) value. This is crucial for faithfully reproducing colors like the crimson veins in marble or golden crystals in granite. Low-CRI light sources can make stone colors appear dull and flat.

3. Heat Dissipation & Installation: The Invisible Engineering

Integrated Heat Sinking: Even though LEDs generate little heat, in high-brightness, enclosed installations, heat buildup is the primary enemy. Choose panels with integrated aluminum substrates or those compatible with add-on aluminum channels to keep the junction temperature below 65°C. This is the physical foundation for ensuring low light decay and the 50,000-hour lifespan.

Installation Flatness: Any gap between the stone and the panel will cause visibly uneven brightness. Using optical-grade adhesive or mounting clips with evenly distributed pressure is recommended to ensure consistent pressure across the entire contact surface.

Key Installation Process Points

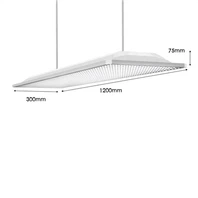

Stone Fabrication Stage: Collaborate closely with the stone fabricator. Finalize stone thickness (typically 12-20mm is suitable), ensure the back surface is ground flat, and precisely pre-drill holes for power cables.

Panel Customization & Testing: Precisely cut and connect the LED panels according to the final stone slab's dimensions and shape. Conduct a powered test before installation to check for uniformity and color temperature.

Substructure Preparation: Pre-install power cables and drivers on the mounting substrate (e.g., wall, cabinet), leaving space for heat dissipation. Drivers should be placed in easily accessible locations.

Layered Installation: Follow this sequence: Install the substrate → Secure the LED panels (ensuring flatness) → Connect and conceal wiring → Finally, mount the stone panel. Using an adjustable dry-hanging system is recommended for easier future fine-tuning.

FAQ

Q1: Can LED backlighting cause marble or granite to crack from heat?

A: Standard high-quality LED panels typically have a surface operating temperature below 50°C, far below the threshold for thermal stress cracking in stone. The main risks stem from two factors: 1) using inferior, non-heat-sinked LED products, and 2) installing the fixtures in a completely sealed stone cavity with no airflow. Choosing panels with aluminum substrate heat sinking and incorporating minimal ventilation space in the design can completely avoid this issue.

Q2: How can electrical safety be ensured for a backlit marble wall in a wet area like a bathroom?

A: This is an area requiring extreme caution. The solution involves:

Fixture Selection: Must use IP67 or IP68 rated, fully waterproof LED strips or panels.

Power Supply Isolation: The driver/power supply must be installed in a dry location outside the bathroom zone (e.g., a neighboring cabinet or ceiling access panel).

Professional Installation: All connections must use waterproof junction boxes and be performed by a licensed electrician, ensuring compliance with local safety codes.

Q3: What if the backlit stone shows decreased brightness or color inconsistency after years of use?

A: This is typically a result of inconsistent LED lumen depreciation or the use of early-generation, low-quality products. Prevention is better than cure:

Choose Low-Lumen-Depreciation Products: Ask suppliers for the "L70 lifetime" data (hours until luminous flux maintenance drops to 70%). High-quality products should exceed 50,000 hours.

Use a Single Batch: All panels for one project must be from the same manufacturing batch to avoid initial color temperature variances.

Modular Design: At the design stage, consider dividing the backlighting system into several independently removable modules (e.g., one per square meter). This allows for future replacement without dismantling the entire stone surface.

References & Citations

Stone light transmittance data references the measured statistical ranges for stone physical properties published in the Natural Stone Characteristics Guide by the Marble Institute of America (MIA).

The relationship between LED lumen depreciation and junction temperature follows the Arrhenius model, with relevant testing standards referenced from IES LM-80-15 Measuring Lumen Maintenance of LED Light Sources and TM-21-11 Projecting Long-Term Lumen Maintenance of LED Light Sources.

Design recommendations for lighting uniformity (Uniformity Ratio) synthesize references from the *DG-18-08 Lighting for Building Surfaces Design Guide* published by the Illuminating Engineering Society of North America (IESNA).

Electrical safety standards for bathroom areas refer to the special requirements of the International Electrotechnical Commission standard IEC 60364-7-701: *Electrical installations of buildings - Part 7-701: Requirements for special installations or locations - Locations containing a bath or shower*.