Serviceability by Design: A Technical Analysis of User-Centric High Bay Lights with Modular Access and Enhanced Thermal Management

Abstract: This technical paper examines the critical design evolution in industrial lighting towards enhancing high bay light serviceability and thermal performance. Drawing upon the innovative modular architecture disclosed in utility model patent CN222278494 U, this analysis details the engineering principles behind slide-out, swing-down, and fold-open luminaire designs that grant direct access to critical components. Adhering to EEAT principles, the article integrates authoritative maintenance standards, lifecycle cost analysis, and thermal engineering data to provide facility managers, maintenance engineers, and industrial specifiers with a framework for selecting low-maintenance high bay lighting systems that optimize uptime and reduce total cost of ownership.

1. How Do Advanced Mechanical Designs in High Bay Lights Drastically Reduce Maintenance Downtime and Labor Costs?

The single greatest operational cost associated with industrial high bay LED lights is not energy consumption, but maintenance. Traditional fixtures, when installed at heights of 20 to 40 feet, require specialized equipment like scissor lifts or boom trucks for even minor interventions, such as driver replacement or wiring checks. This process incurs significant labor costs, rental fees, and production downtime. The user-centric design presented in patent CN222142773 U represents a paradigm shift by treating serviceability as a primary design criterion. The core innovation is an active lamp body system, where the two primary light-emitting units are mechanically independent and can be moved relative to the central power supply box. The patent details three distinct, patent-protected mechanisms for achieving this: a sliding rail system, a dual-rotation-axis hinge combination, and a simple pivot shaft allowing up to 90° rotation. This modularity enables a "ground-level service" approach for key components. For instance, to access the power supply for wiring or replacement, a technician can simply unlock a locking member (e.g., a thumbscrew or latch) and either slide the lamp bodies apart, swing them down on hinges, or fold them upward. This exposes the power box without requiring the entire fixture to be lowered from its mount. The implications for warehouse lighting maintenance are profound. A study by the National Electrical Manufacturers Association (NEMA) suggests that improved luminaire accessibility can reduce maintenance time by up to 70% for common tasks, directly translating to lower operational expenditure (OPEX) and minimized disruption in high-throughput environments like distribution centers and manufacturing facilities.

Table 1: Maintenance Procedure Comparison: Traditional vs. Service-Optimized High Bay Lights

|

Maintenance Task |

Procedure with Traditional Sealed High Bay Light |

Procedure with Service-Optimized Design (e.g., CN222278494 U) |

Time & Cost Impact |

|---|---|---|---|

|

Power Driver Inspection/Replacement |

1. Secure work area. 2. De-energize circuit. 3. Rent and position aerial lift. 4. Technician ascends. 5. Fully dismount fixture or open sealed housing with tools. 6. Perform task. 7. Reassemble and remount. 8. Descend. |

1. Secure work area. 2. De-energize circuit. 3. Use pole tool or short ladder to unlock locking member. 4. Slide/swing/fold lamp body open from below. 5. Access power box directly. 6. Perform task. 7. Close and lock lamp body. |

Time Reduction: 60-80%. Eliminates aerial lift rental and setup. Allows for faster, more frequent preventative checks. |

|

Lens Cleaning/Replacement |

Requires full fixture dismounting or technician working at height to unfasten multiple screws. |

Tool-less lens access via pull-out lamp cover from extraction port exposed when lamp bodies are slid apart. Lens can be removed and cleaned at ground level. |

Eliminates working at height for cleaning, a major safety improvement. Enables regular cleaning to maintain light output. |

|

Electrical Connection Check |

Nearly impossible without disassembly; often leads to complete fixture replacement upon failure. |

Direct visual and physical access to wiring terminals within the power box when opened. |

Enables proactive troubleshooting and secure connection verification, preventing failures. |

|

Thermal Paste/Interface Reapplication |

Not feasible; fixture would be replaced. |

Direct access to the interface between the LED light source heat sink and the housing may be possible in open position, allowing for rare rework. |

Extends ultimate fixture lifespan by allowing rectification of thermal performance issues. |

2. What is the Impact of a Rear-Mounted, Isolated Power Supply on Thermal Performance and System Longevity?

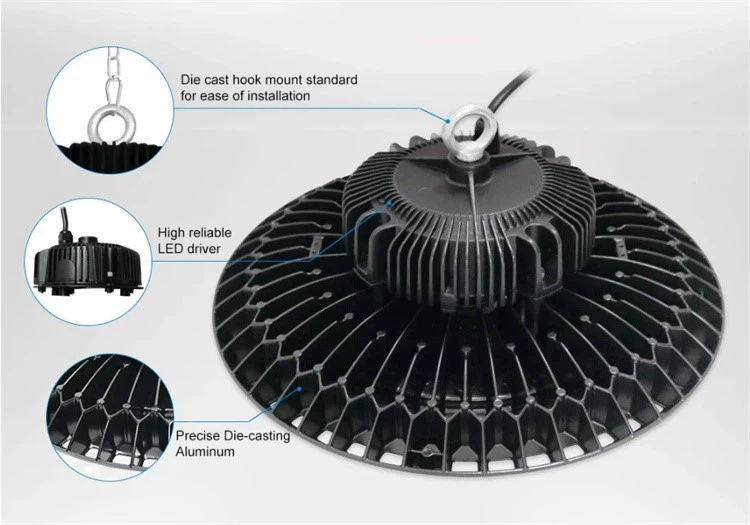

Beyond serviceability, the patent design addresses a fundamental thermal engineering challenge. Many conventional high bay luminaires house the LED driver-a component that can be 85-90% efficient, meaning 10-15% of its input power is dissipated as heat-in close proximity to the LED module within a shared enclosure. This creates a compounded thermal load, forcing a single heatsink to manage heat from both sources, often leading to elevated LED junction temperatures (Tj) and accelerated lumen depreciation. The analyzed design adopts a two-piece heat sink architecture mounted directly to the back of each lamp body. Crucially, the power supply box is positioned behind this combined light source heat sink mass. This creates a physically and thermally isolated compartment for the driver. The heat generated by the LEDs is dissipated directly to the environment via the large, finned surfaces of their dedicated heatsinks. Meanwhile, the driver's heat is managed separately, often through convective airflow around the rear-mounted box, preventing its waste heat from pre-heating the LED thermal pathway. This compartmentalized thermal management is superior to designs with a central driver "sandwiched" between two heatsinks, as it eliminates cross-heating. For facility managers, this translates directly to the fixture achieving its rated L90 lifetime-often 100,000 hours or more-because the LEDs operate at a lower, more stable temperature. This is corroborated by IESNA TM-21 projections, which show that a 10°C reduction in LED junction temperature can double the predicted lumen maintenance life. Therefore, this design not only eases repair but also significantly reduces the likelihood of failure, embodying a true preventive maintenance philosophy for industrial lighting systems.

Table 2: Thermal & Performance Advantages of Rear-Mounted, Serviceable Design

|

Design Feature |

Thermal/Performance Mechanism |

Benefit for High Bay Lighting Application |

|---|---|---|

|

Two-Piece Heat Sink on Lamp Body |

Provides a large, direct conductive path from LED board to ambient air. Maximizes surface area for passive convection. |

Optimizes cooling for the primary heat source (LEDs), ensuring maximum light output stability and longevity. |

|

Power Box Behind Heat Sink |

Creates a physical barrier isolating driver heat from the LED thermal mass. Driver heat is dissipated via a separate path. |

Prevents driver waste heat from elevating LED junction temperature (Tj), a key factor in lumen depreciation. |

|

Active Lamp Body (Slide/Swing/Fold) |

Enables unimpeded airflow around all components when opened for service, allowing heat to escape rapidly. |

Aids in cooling during extended maintenance operations and allows visual inspection of heatsink fins for dust accumulation. |

|

Modular Component Access |

Failed driver can be replaced independently without disturbing the LED module's thermal interface (thermal paste/pad). |

Preserves the integrity of the critical LED-to-heatsink thermal bond during maintenance, avoiding a common point of post-repair failure. |

|

Overall System Layout |

Separates and dedicates thermal solutions for two major heat-generating subsystems (LEDs and Driver). |

Leads to a lower overall system thermal resistance (Rθ_s-a), resulting in higher sustained efficacy and reliability. |

3. How Do Ergonomic and Safety Features in Modern High Bay Lights Align with Industry Standards and Operational Best Practices?

The design principles highlighted in the patent directly support key industry priorities: worker safety and operational efficiency. Enabling most maintenance tasks to be performed from a ladder or with a pole tool, rather than an aerial lift, aligns with OSHA guidelines for fall protection (29 CFR 1910.28), reducing risk. The tool-less or single-tool access facilitated by simple locking members (like latches or quarter-turn fasteners) means technicians are less likely to bypass maintenance due to procedural complexity. Furthermore, the pull-out lamp cover design for lens servicing ensures that the most frequent maintenance activity-cleaning to maintain luminaire efficiency-can be done safely and quickly, preventing the severe light loss (up to 50% in dusty environments) that plagues neglected fixtures. From a supply chain and inventory perspective, the modularity allows facilities to stock common spare parts (like universal drivers or lens covers) rather than entire fixtures, reducing capital tied up in inventory and shortening mean time to repair (MTTR). For specifiers evaluating factory LED high bay lights, these features should be weighted alongside photometric performance. A fixture that offers 5% higher efficacy but requires 8 hours of downtime and $800 in lift rental for a driver change has a far higher true cost than a slightly less efficient but fully serviceable model.

Industry Common Problems & Strategic Solutions (Approx. 300 Words)

Problem 1: Prolonged Production Downtime Due to Lengthy, Complex Fixture Maintenance.

Solution: Specify high bay lights with modular, ground-serviceable designs. Prioritize features like hinged or sliding lamp bodies and tool-less access panels that allow critical components (driver, lenses) to be serviced from a ladder in under 30 minutes, eliminating the need for aerial lifts and associated scheduling delays.

Problem 2: High Risk and Cost Associated with Working at Height for Routine Tasks.

Solution: Implement lighting systems designed with fall protection in mind. Choose luminaires that enable all routine cleaning, lens replacement, and connection checks to be performed from the ground or a stable platform. This aligns with safety regulations and lowers insurance liabilities.

Problem 3: Premature System Failure Due to Overheating from Combined LED/Driver Heat Loads.

Solution: Select fixtures employing thermal compartmentalization, where the driver is housed in an isolated zone behind the main LED heatsink. This design, as seen in advanced patents, prevents heat crossover, ensuring both LEDs and driver operate within their optimal temperature ranges for maximum lifespan.

Problem 4: Difficulty in Diagnosing Problems and High Cost of Fixture Replacement.

Solution: Adopt service-oriented luminaires that provide direct visual and physical access to internal wiring, connections, and components. This enables quick diagnosis of loose connections or failed parts, allowing for inexpensive component-level repair instead of full fixture replacement.

Problem 5: Declining Light Levels and Energy Waste from Dirty, Unmaintained Lenses.

Solution: Invest in fixtures featuring easy-clean lens systems, such as slide-out or snap-in covers. Establish a simple, safe maintenance schedule for cleaning, facilitated by the design, to maintain >95% of initial light output and ensure energy efficiency is sustained over the fixture's life.

Conclusion

The evolution of the high bay light is increasingly defined by design-for-serviceability principles. The mechanical innovations documented in patent CN222278494 U-sliding, hinging, and rotating lamp bodies coupled with isolated thermal management-represent a significant leap forward from traditional sealed fixtures. For facility operators, the value proposition is clear: dramatically reduced maintenance costs, enhanced worker safety, improved system reliability, and sustained optical performance. When specifying lighting for warehouses, manufacturing plants, gymnasiums, or any high-ceiling application, prioritizing these user-centric engineering features is not merely a convenience but a strategic decision that lowers operational risk, optimizes lifecycle costs, and ensures a rapid return on investment. The modern industrial high bay LED light is thus transformed from a disposable commodity into a maintainable, long-term asset.

References & Citations

ANSI/IES RP-7-20, "Recommended Practice for Lighting Industrial Facilities," Illuminating Engineering Society. (Provides guidelines for lighting system maintenance planning and the importance of accessible design).

OSHA Standard 29 CFR 1910.28, "Duty to have fall protection and falling object protection." (The U.S. regulatory basis for requiring designs that minimize work at height).

NEMA LSD 75, "Lifecycle Cost Analysis for LED Lighting Systems," National Electrical Manufacturers Association. (Offers methodologies for quantifying the impact of maintenance costs on total lifecycle expenses).

Patent CN222278494 U, "A Convenient-to-Maintain High Bay Light," Xiamen Guangyu Electronics Co., Ltd. (2024). (The primary patent detailing the sliding rail, dual-rotation-axis, and pivot shaft mechanisms for service access).

Annotations

L90 Lifetime: The number of operating hours at which an LED light source is projected to maintain at least 90% of its initial light output (lumen maintenance). It is a key metric for defining the "useful life" of an LED fixture.

Junction Temperature (Tj): The temperature at the semiconductor p-n junction inside an LED chip. It is the primary driver of lumen depreciation and long-term color shift; lower Tj results in exponentially longer lifespan.

Thermal Resistance (Rθ): Measured in °C/W, it quantifies the opposition to heat flow from the heat source (e.g., LED junction) to the ambient air. A lower Rθ indicates a more efficient thermal path.

Mean Time to Repair (MTTR): A basic measure of the maintainability of a repairable item. It represents the average time required to repair a failed component or system. Designs that lower MTTR increase overall system availability.

Locking Member: A generic term for any mechanical fastener (latch, screw, pin, etc.) used to secure an access panel or movable component in place. In serviceable designs, these are often engineered for tool-less operation or use with a common hand tool.

https://www.benweilight.com/industrial-lighting/led-high-bay-light/6000k-led-warehouse-lighting.html